erp selection

Being platform agnostic, we analyze your business and its specific needs and offer a solution that is customized to meet them. Cumulus will work with you to identify the right solution for your organization.

Learn more

Being platform agnostic, we analyze your business and its specific needs and offer a solution that is customized to meet them. Cumulus will work with you to identify the right solution for your organization.

Learn more

Working with the right Enterprise Resource Planning implementation partner is key to the success of your ERP. Through our proven ERP implementation strategies and decades of experience, we provide our clients with the highest level of expertise they can find.

Learn more

Our extensive manufacturing experience allows us to strategically consult with our customers and develop optimization plans for SAP, Plex, and other ERP softwares to help their businesses operate as effectively as possible.

learn moreIn everything we do, we believe in thinking outside the box, in challenging the status quo, and in solving problems in innovative ways. We strive to inspire our customers, our employees, and our partners to conceive of limitless possibilities. We didn’t invent the “can do” spirit, but we do embrace it and it is our underlying and driving core value.

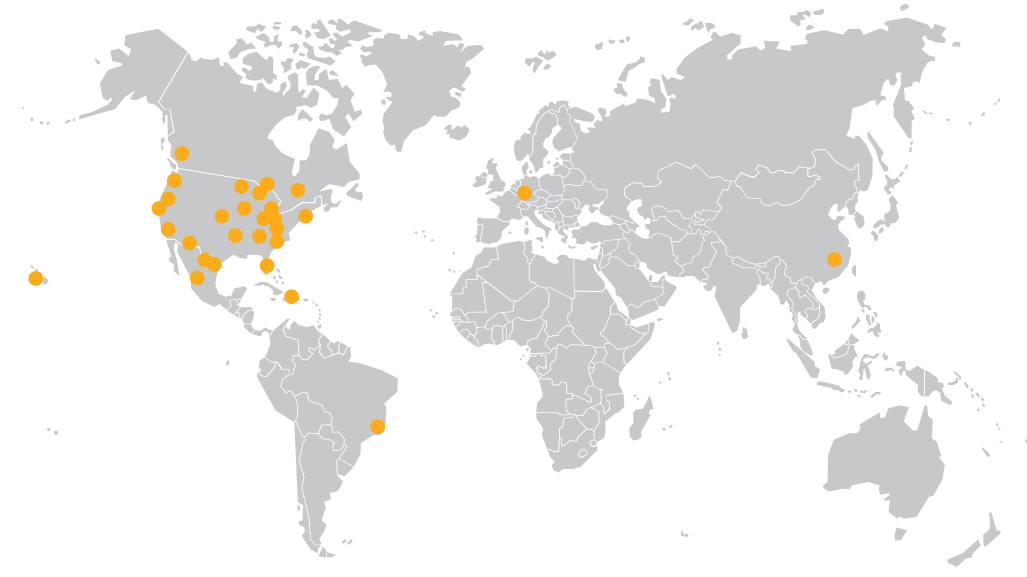

Cumulus is a full-service ERP and technology consulting firm with a special focus on developing digital transformation solutions for manufacturers.

Cumulus Consulting partners with leading software and systems solution providers.

view allWe offer our services across many verticals, specializing in:

We create solutions for manufacturers in the rapidly changing rubber and plastics industry.

Learn more

We develop tightly integrated software solutions to meet the unique challenges of this highly regulated field.

Learn more

We enable our clients to work more efficiently while meeting the industry’s stringent requirements.

Learn more

We help you exceed consumers’ expectations through accurate market insights in real time.

Learn more

We optimize your supply chain, warehousing, and logistics management processes.

Learn more

We maximize your ability to respond faster to demand in this ever-changing, dynamic environment.

Learn more

We empower you with the ability to grow and adapt to changing inventory and supply chain management requirements.

Learn more

We improve upon your existing strategies to enable you to meet fluctuating demands with efficiency.

Learn more

We modernize business processes while enabling you to carry on the legacy of this highly respected industry.

Learn moreOlde Thompson fulfills our clients web orders direct to consumer and ships approximately 300 parcel packages per week. Cumulus has made it possible for us to do that through their integration with Plex and their Chrome App without the need for manual entry. This allows us to ship not only with our own Parcel accounts, but also utilizing our clients Parcel accounts. This tool has allowed us to streamline our process easily and effectively with minimal errors. Lance, Craig, and the rest of the team at Cumulus made themselves available to tweak the product to our needs as we went Live with Plex and were readily available to assist and train with any questions or issues that we had. We are very happy with the product and with the service we received while rolling out this new product, we look forward to a long relationship with Cumulus and Plex.

Through the tremendous help we had from the Cumulus team, it made it easy. Basically, all I had to do was see the big picture and have them help guide us to get to that point. A lot of the Cumulus employees are former Plex employees, so they were very knowledgeable about the system and able to give an unbiased view of some of the strengths and weaknesses. And we think we’ve captured most of the strengths we’re able to work like partners throughout the whole process.

We had many choices when picking an implementation partner, but to us there was only one choice, Cumulus! Their knowledge of manufacturing and Plex was without question the best we have ever seen in a service partner.

I wanted to pass along a note about our Plex consultant, Jason Delozier and his company, Cumulus Consulting. He has held a crucial role in our successful implementation of Plex at GenZe. I can’t say enough great things about Jason and his team! If our story is told, I feel it only appropriate to credit a piece of our growing success to Cumulus and their ability to leverage a great relationship with your team.

Everyone at Cumulus was extremely knowledgeable and friendly. Their unique approach to training enabled us to work closely with them over a nine-month period and build our own information. As a result, not only do our day-to-day users have a great understanding of Plex, but our managers are really comfortable with it, too.

Working with a like-minded group driven to make their customers succeed through the use of new technologies.

Utilizing the flexibility of MFGx integration and Ignition to design customized analytic data as well as help us integrate printing processes directly from Plex.

We appreciate working with consultants who are willing to engage with us as collaborators. Cumulus has always been willing to join our teams and process problems and ideas with us.

We also know that if we run into a dead end on a technical issue, the team at Cumulus won’t just clear the path, they will be willing to discuss how that path can be cleared.

They are always inclined to share knowledge, which doesn’t just support our technical needs – it helps us develop our own skill sets internally.

Thank you for subscribing!